Ever-Power Group

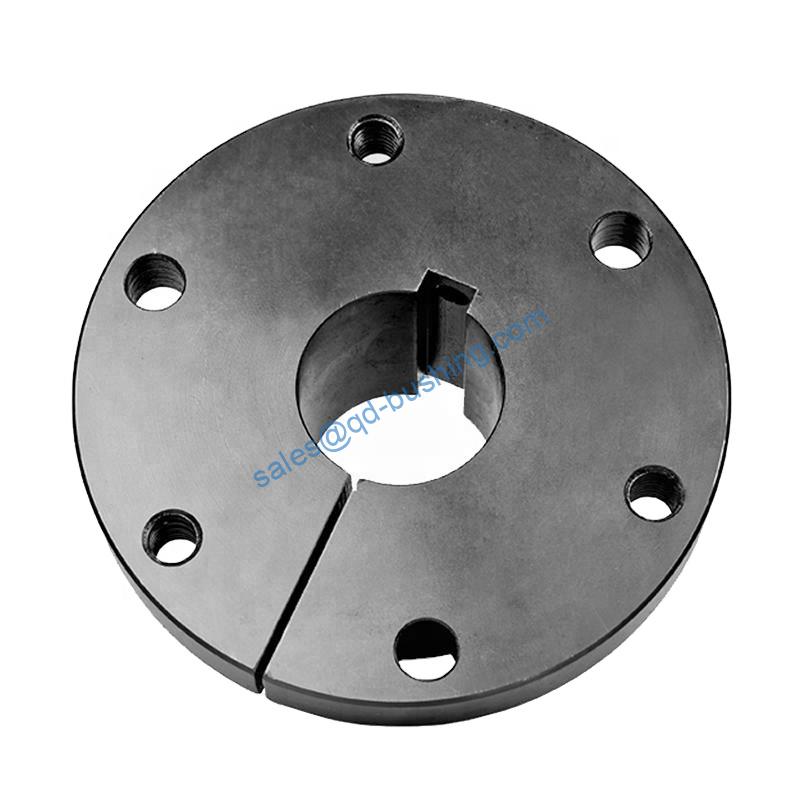

QD Bushing

The bushing is a matching part used outside the mechanical parts to achieve the functions of sealing, wear protection, etc. It refers to the ring sleeve that functions as a gasket.

What we do

We can produce customized gearboxes, gear motors, electric motors and other hydraulic products according to customers’ drawings.

Bushing function

The flexibility of the bushing is relatively high. Generally speaking, the bushing is a kind of component that protects the equipment. The use of bushings can reduce equipment wear, vibration and noise, and has an anti-corrosion effect. The use of the bushing can also facilitate the maintenance of mechanical equipment and simplify the structure and manufacturing process of the equipment.

Bushing material

The material of the bushing is mostly soft metal, rubber, nylon and non-metallic polymers, etc. These materials have relatively soft texture and low cost. In a variety of harsh working environments, the bushing is subjected to vibration, friction and corrosion to protect the wrapped parts, and the bushing itself is easy to replace after being damaged, with low cost and good economy.

Selection factors

Bushings have a wide range of applications and there are many types. To choose a suitable bushing, you must consider its purpose of use, and choose different types of bushings for different working conditions. The main consideration in the selection of the bushing is the pressure, speed, pressure-speed product and load properties that the bushing needs to withstand.

Bushing

In the moving parts, the parts are worn out due to long-term friction. When the gap between the shaft and the hole is worn to a certain extent, the parts must be replaced. Therefore, the designer chooses the lower hardness and better wear resistance when design The material is shaft sleeve or bushing, which can reduce the wear of shaft and seat

- Application: packaging machinery, textile machinery, mining machinery, metallurgical machinery, printing machinery, tobacco machinery, forging machinery, various types of machine tools and interchangeable machinery transmission coupling. For example: pulleys, sprockets, gears, propellers, large fans and various other connections, etc.

“

Features: large torque, high accuracy, convenient and quick assembly and disassembly, simple operation, good positioning, reduced scrap rate of matched shafts and hubs, reusable use, and no damage to the mating surface. It is currently the most ideal and economical choice.

“

Ever-Power Group

QD Bushing

Wrapped in the valve stem, worn out, can be replaced easily. If the bushing is not used, the parts are replaced after wear. Therefore, the replacement is to replace the bushing (in the design, the hardness of the bushing is reduced to make it a wear-bearing part in the friction pair). Because of its convenient processing, low replacement cost and easy replacement. Of course, there is a guiding role, etc., which is second.

20+

More than 20 years experience in research and development.

Features

The IKO miniature linear bush bearing is an extremely small linear motion guide that rotates with the shaft, makes infinite linear motion in the direction of the shaft while contacting, and has a shaft diameter of 3~5mm. Features are:

1. Low frictional resistance: The steel ball can perform stable linear motion with extremely small frictional resistance due to the correct orientation of the retainer.

2. Stainless steel: stainless steel series are also available, suitable for applications requiring corrosion resistance.

3. Exquisite design: extremely small in size and can be designed in exquisite mechanical equipment.

4. Abundant changes: In addition to the standard type, there are also a series of high-rigidity long type, which can be selected according to the purpose.